A pile driver is a heavy-duty machine used in construction to drive piles long structural supports deep into the ground. These piles provide foundation stability for buildings, bridges, and other large structures. Pile drivers are essential for construction projects on weak or unstable soil, ensuring a strong and durable foundation.

This topic explains the types, functions, components, and uses of pile drivers in modern construction.

1. What Is a Pile Driver?

A pile driver is a piece of heavy machinery designed to hammer piles into the ground to create a stable foundation for buildings, bridges, docks, and other structures. The machine uses impact or vibration to drive piles deep into the soil, ensuring the structure remains secure.

Piles can be made of steel, concrete, or wood, depending on the project requirements.

Why Are Pile Drivers Important?

✔ Provide Strong Foundations – Ensures buildings and structures remain stable

✔ Support Large Loads – Helps structures withstand heavy weight and pressure

✔ Prevent Soil Shifting – Reduces the risk of settlement or foundation failure

✔ Essential for Coastal and Offshore Construction – Used for bridges, docks, and wind farms

2. How Does a Pile Driver Work?

A pile driver operates by lifting a heavy weight and dropping it onto a pile, forcing it into the ground. Some pile drivers use vibrations or hydraulic pressure instead of direct impact to push piles into the soil more efficiently.

Main Steps in Pile Driving

-

Positioning the Pile – The pile is placed in the correct location on the construction site.

-

Lifting the Hammer or Vibrator – The pile driver raises a weight or starts vibration.

-

Driving the Pile – The weight is released, or vibrations push the pile deeper into the ground.

-

Checking Depth and Stability – Engineers ensure the pile is deep enough to provide stability.

3. Types of Pile Drivers

There are several types of pile drivers, each suited for different construction projects.

A. Drop Hammer Pile Driver

✔ Uses a heavy weight lifted and dropped onto the pile

✔ Simple and cost-effective but slower than modern methods

✔ Suitable for smaller construction projects

B. Diesel Hammer Pile Driver

✔ Uses combustion pressure to lift and drop the hammer

✔ Fast and powerful, ideal for large construction projects

✔ Commonly used in bridge and skyscraper foundations

C. Hydraulic Hammer Pile Driver

✔ Uses hydraulic force instead of combustion or gravity

✔ Provides more control and efficiency

✔ Reduces noise and vibrations, making it environmentally friendly

D. Vibratory Pile Driver

✔ Uses high-frequency vibrations instead of impact force

✔ Ideal for driving and removing piles

✔ Often used in coastal and offshore projects

E. Hydraulic Press-In Pile Driver

✔ Pushes piles into the ground without impact or vibration

✔ Best for urban areas where noise and disturbance must be minimized

✔ Used in projects near existing buildings or sensitive environments

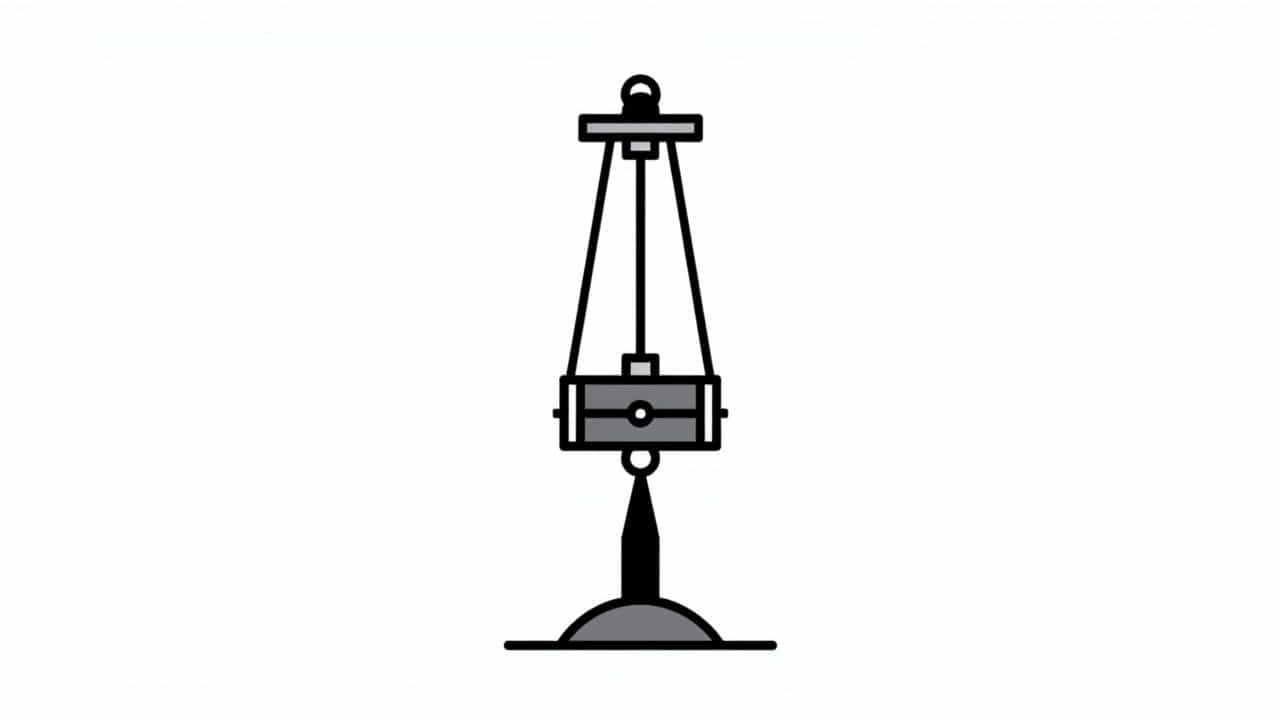

4. Components of a Pile Driver

A pile driver consists of several key parts that work together to drive piles efficiently.

✔ Hammer or Vibratory Unit – The main force that pushes the pile into the ground

✔ Pile Frame – Supports and guides the pile into position

✔ Power Source – Provides energy for lifting or vibrating the hammer

✔ Leads – Keeps the pile aligned during installation

✔ Winch System – Lifts and lowers the hammer in drop hammer systems

5. Where Are Pile Drivers Used?

Pile drivers are essential for various construction projects that require deep and stable foundations.

Common Applications

✔ Building Foundations – Used in skyscrapers, bridges, and residential buildings

✔ Marine and Coastal Construction – Essential for docks, piers, and offshore wind farms

✔ Railway and Highway Construction – Supports bridges and overpasses

✔ Industrial Structures – Provides stability for factories and power plants

6. Advantages of Using a Pile Driver

Using a pile driver offers several benefits in modern construction.

✔ Increases Structural Stability – Ensures buildings can withstand weight and environmental forces

✔ Speeds Up Construction – Faster than manual or traditional piling methods

✔ Works in Various Soil Conditions – Effective in sand, clay, and loose soil

✔ Reduces Long-Term Maintenance – A strong foundation prevents costly repairs

7. Challenges of Pile Driving

Despite its benefits, pile driving also comes with some challenges.

✔ Noise and Vibrations – Can be disruptive in urban areas

✔ High Equipment Costs – Pile drivers are expensive to buy and maintain

✔ Requires Skilled Operators – Operating a pile driver requires training and experience

✔ Environmental Concerns – Can disturb marine life and nearby buildings

8. How to Become a Pile Driver Operator

Operating a pile driver requires technical training and hands-on experience.

Steps to Become a Pile Driver Operator

-

Obtain a High School Diploma or GED – Basic education is recommended.

-

Complete Heavy Equipment Training – Many vocational schools offer courses in pile driving and construction machinery.

-

Gain Hands-On Experience – Apprenticeships or on-the-job training are essential.

-

Obtain Certification – Some areas require certifications for safety and operational standards.

-

Apply for a Commercial Driver’s License (CDL) (Optional) – Some operators need a CDL to transport heavy equipment.

A pile driver is an essential piece of construction equipment that ensures strong and stable foundations for buildings, bridges, and other structures. With different types of pile drivers available, construction teams can choose the best method for their project needs.

Despite its challenges, pile driving remains a vital part of modern construction, helping to create durable and long-lasting infrastructure worldwide.